Descripción del Producto:

I. Propiedades del Material Principal

El material del diafragma de la válvula de pulso es clave para determinar su rendimiento. Los diafragmas de las válvulas de pulso Dahe utilizan principalmente materiales elastómeros. Los tipos comunes y sus características son los siguientes:

Caucho de nitrilo butadieno (NBR):

Ventajas: Buena resistencia al aceite, adecuado para condiciones de trabajo con niebla de aceite; elasticidad moderada y bajo costo.

Limitaciones: Resistencia general a la temperatura (generalmente -20℃~120℃), débil resistencia al envejecimiento por ozono.

Fluoroelastómero (FKM):

Ventajas: Excelente resistencia a altas y bajas temperaturas (-20℃~por encima de 200℃), fuerte resistencia a la corrosión química, el ozono y el envejecimiento, adecuado para condiciones de trabajo a alta temperatura y corrosivas (como la industria química, la industria metalúrgica).

Limitaciones: Mayor costo, elasticidad ligeramente inferior a la del caucho de nitrilo.

Monómero de etileno propileno dieno (EPDM):

Ventajas: Buena resistencia a la intemperie y al ozono, resistente al vapor de agua y a la corrosión por ácidos débiles, y aplicable a un amplio rango de temperaturas (-40℃~150℃).

Limitaciones: Poca resistencia al aceite, no adecuado para entornos que contengan aceite.

Algunos modelos de alta gama utilizarán materiales compuestos (como caucho combinado con esqueleto de tela) para mejorar la resistencia al desgarro y la resistencia.

II. Propiedades físicas y mecánicas

Elasticidad y Resiliencia:

El diafragma necesita abrirse y cerrarse rápidamente bajo el impacto del flujo de aire pulsado de alta frecuencia (varias a docenas de veces por minuto). Por lo tanto, debe tener una alta elasticidad para asegurar que la superficie de sellado se ajuste herméticamente sin fugas; la resiliencia asegura que no sea fácil de deformar después de un uso prolongado.

Resistencia a la tracción y resistencia al desgarro:

Durante el funcionamiento, el diafragma estará sujeto a la fuerza de tracción generada por la presión del aire. Una resistencia a la tracción insuficiente puede provocar fácilmente la rotura; la resistencia al desgarro evita una mayor expansión de los bordes o áreas pequeñas dañadas, extendiendo la vida útil.

Dureza:

Generalmente se utilizan materiales con una dureza Shore de 60~80A. Una dureza demasiado baja puede provocar fácilmente un sellado deficiente, y una dureza demasiado alta afectará la elasticidad y la velocidad de respuesta.

Resistencia a la temperatura:

El material adecuado se selecciona de acuerdo con la temperatura de trabajo. Por ejemplo, se necesitan diafragmas de fluorocaucho para colectores de polvo de alta temperatura (temperatura de los gases de combustión superior a 120℃), y se pueden utilizar diafragmas de caucho de nitrilo para condiciones de trabajo a temperatura normal.

III. Características de trabajo

Rendimiento de sellado:

La superficie de ajuste entre el diafragma y el asiento de la válvula debe procesarse con precisión para garantizar un sellado completo cuando no hay señal de pulso, evitando fugas de aire comprimido y evitando el desperdicio de energía y la reducción de la eficiencia de eliminación de polvo.

Velocidad de respuesta:

Activado por la señal de control de pulso, necesita abrirse rápidamente (generalmente en milisegundos) para hacer que el aire comprimido se rocíe en la bolsa del filtro instantáneamente para completar la limpieza de cenizas; también se cierra rápidamente para reducir el tiempo de chorro no válido.

Resistencia al medio:

Necesita soportar la humedad y las manchas de aceite en el aire comprimido (o aire limpio después del secado y la purificación), así como el polvo que puede regresar (como cuando la bolsa del filtro está dañada). Por lo tanto, debe tener las características de resistencia al desgaste y resistencia a la erosión química.

Parámetros técnicos:

|

|

|

|

Modelo de válvula de pulso ajustada

|

|

|

|

|

|

|

TH-5820-B

TH-4820-B

TH-5825-B

TH-5820-C

TH-4820-C

|

|

|

|

|

|

|

TH-4825-B

TH-5825-C

TH-4825-C

TH-5840-F

TH-4840-F

|

|

|

|

|

|

|

|

|

|

TH-5840-B

TH-5440-B

TH-4840-B

TH-4440-B

TH-5840-C

TH-5440-C

TH-4840-C

TH-4440-C

TH-5850-F

TH-5450-F

TH-4850-F

TH-4450-F

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TH-5460-B

TH-4460-B

TH-5460-S

TH-4460-S

|

|

|

|

|

|

|

|

|

|

|

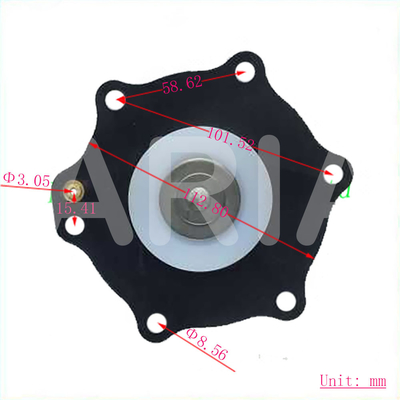

Dimensión del diafragma MD01-40, MD02-40, MD03-40:

Diafragma principal:

Diafragma secundario:

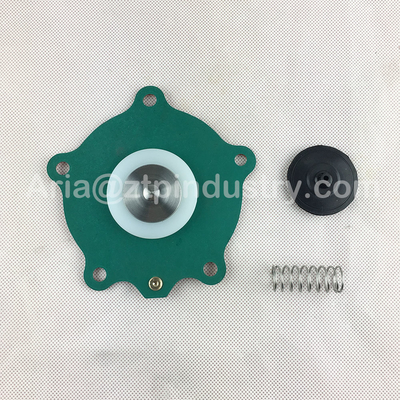

Imágenes de Membrana de la válvula solenoide Producción:

|

|

Aplicaciones:

Adaptación de las condiciones de trabajo: El material se selecciona de acuerdo con la temperatura del sistema de eliminación de polvo, el medio (que contiene aceite, gas corrosivo, etc.) y la presión del pulso (generalmente 0,2~0,6 MPa). Por ejemplo:

- Entornos corrosivos como plantas de incineración de residuos y talleres químicos → diafragmas de fluorocaucho;

- Entornos a temperatura normal y no corrosivos como el procesamiento de madera y el procesamiento de granos → diafragmas de caucho de nitrilo.

Vida útil

En condiciones de trabajo normales, la vida útil de los diafragmas de alta calidad puede alcanzar los 100.000~300.000 ciclos de pulso (aproximadamente 1~3 años), lo que depende del material, la temperatura de trabajo, la frecuencia de pulso y las condiciones de mantenimiento. Un mantenimiento inadecuado (como una gran cantidad de humedad en el aire comprimido que conduce al envejecimiento acelerado del diafragma) acortará significativamente su vida útil.

En conclusión, las propiedades principales del diafragma de la válvula de pulso Dahe se pueden resumir como " alta elasticidad, fuerte sellado, resistencia a la fatiga y fuerte adaptabilidad ". Su rendimiento está directamente relacionado con el funcionamiento estable de la válvula de pulso e incluso de todo el sistema de eliminación de polvo. Al seleccionar, se deben considerar de forma integral el material, el tamaño y las propiedades mecánicas en combinación con las condiciones de trabajo reales.

Embalaje y envío:

Producto: Diafragma de válvula de pulso

Descripción: Este diafragma de válvula de pulso de alta calidad está diseñado para un rendimiento y durabilidad óptimos en diversas aplicaciones industriales.

El paquete incluye: - 1 diafragma de válvula de pulso

Información de envío: - Método de envío: Envío estándar - Tiempo estimado de entrega: 3-5 días hábiles - Costo de envío: $9.99

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!